Students develop wire-arc additive manufacturing desktop printer

- 12.08.2024

- Practical Project

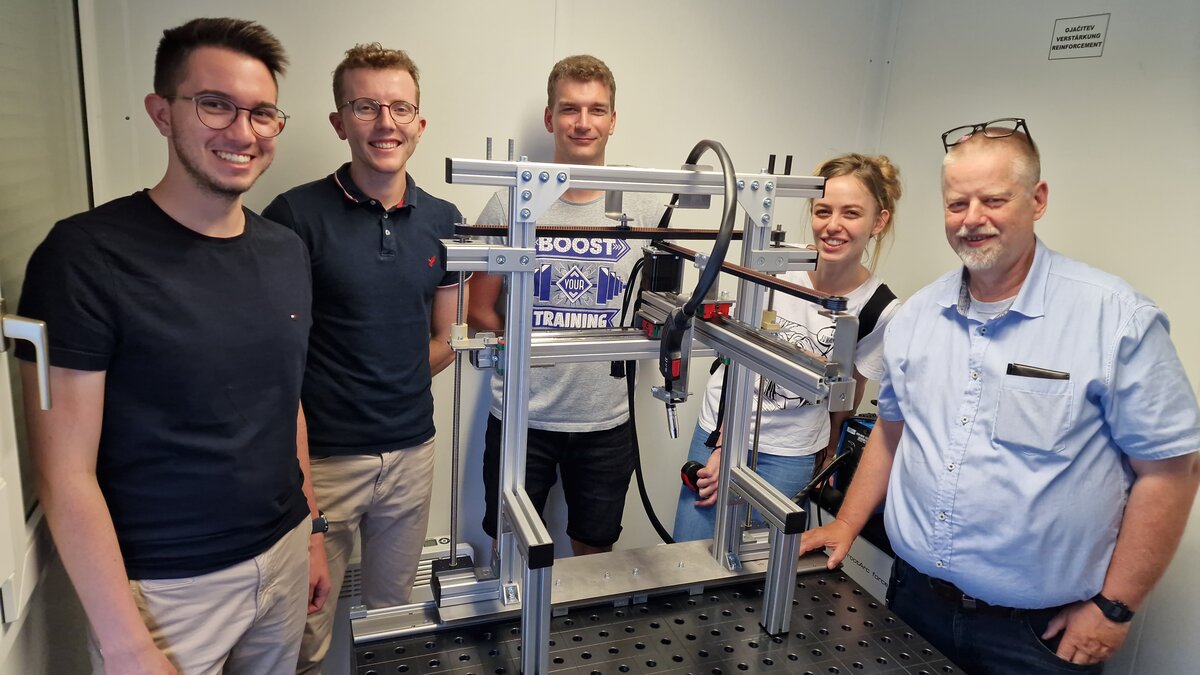

Part of the practical project team and the two clients with the finished Wire-Arc Additive Manufacturing desktop printer.

A practical project from the bachelor's degree program in industrial engineering and management consisting of six students was given the task of developing a compact and cost-effective 3D printer that can print metal and fit on a table.

A Wire Arc Additive Manufacturing (WAAM) desktop printer was developed as part of a practical project in the fourth semester of the Industrial Engineering and Management bachelor's degree program at the University of Applied Sciences Kufstein Tirol. The aim of this project was to develop a compact, low-cost 3D printer that is capable of printing metal and fits on an ordinary table. The project was commissioned by Prof. (FH) Dr. Christian Schmid and Quentin Franz Hirtl, BSc, and accompanied by engineer Markus Ehrlenbach, MSc, as a coach.

The project team passed six students. At the beginning of the project, extensive research and analyses were carried out to define the necessary technical specifications and requirements. These requirements included an installation space of 300 x 300 x 300 millimetres, an interchangeable print bed, linear guidance of all axes and complete shielding against welding spatter. A quick-change system for the welding torch, a positioning accuracy of less than 0.2 millimetres and mounting options for various sensors and additional modules were also provided.

SUCCESSFUL COMPLETION AND HANDOVER

In the course of the project, the concepts and technical solutions were worked out in detail, calculated and finally transferred to the design and assembly of the printer. Some of the required parts were manufactured internally at the University of Applied Sciences and by external suppliers. The mechanical assembly was completed in several phases, with any problems and obstacles that arose being communicated and resolved promptly.

After final adjustment and troubleshooting, the printer was successfully handed over to the customer. The finished WAAM printer will be used in future for research projects in the field of additive manufacturing of metal components and will serve as the basis for further developments and optimizations. The successful implementation of this project demonstrates the high level of commitment and technical skills / competencies of the students involved and represents a significant contribution to research and teaching at the University of Applied Sciences Kufstein Tirol.