Process analysis of robotic mower production at STIHL Tirol

- 11.02.2025

- Practical Project

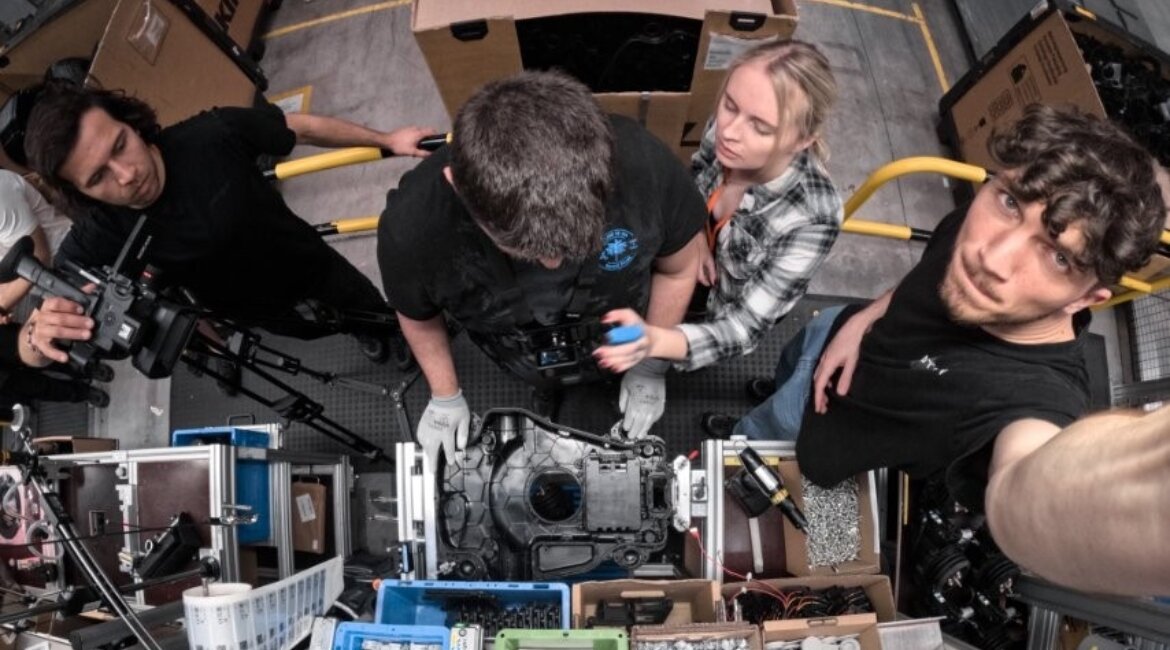

Students and Victor Heim, multimedia designer at the eLearning Center of the University of Applied Sciences Kufstein Tirol (left in picture), setting up the camera with a line employee.

How do you optimize highly complex production processes? Students from the University of Applied Sciences Kufstein Tirol analyzed the production process of the IMOW robotic mower at STIHL Tirol – and not only gained valuable insights, but also identified specific opportunities for improvement.

As part of a practical project, students in the bachelor's degree program in industrial engineering at the University of Applied Sciences Kufstein Tirol carried out a comprehensive process analysis on an IMOW production line at STIHL Tirol. Not only were the manufacturing processes documented in detail, but a complexity assessment was also carried out for the production employees in order to identify optimization potential.

STIHL TYROL AS A PARTNER FOR INNOVATIVE PRODUCTION ANALYSES

STIHL Tirol, based in Langkampfen, is a leading manufacturer of walk-behind and hand-held gardening and forestry equipment. As part of the internationally successful STIHL Group, the company is characterized by innovative technologies and high-quality standards. In particular, the robotic lawn mowers of the IMOW series are a central component of the portfolio of smart products. The continuous improvement process (CIP) is highly valued in the company. This is one of the reasons why the collaboration with the technical degree programs at the Kufstein University was initiated for this project.

PRACTICAL LEARNING AND VALUABLE INSIGHTS

Five students analyzed the production processes of the IMOW assembly line in a five-month project phase. They were supported by the eLearning Center of the Kufstein University as well as by specific training in manufacturing processes, process representation and time recording.

The process was recorded over two days of filming and was based on the MTM (Methods-Time Measurement) methodology. This procedure breaks down workflows into the smallest units of movement and assigns standardized time values to them in order to assess efficiency and ergonomics. In order to obtain reliable data, at least five complete passes were recorded for each process step – so-called assessable passes. These repetitions make it possible to analyze typical procedures and detect variations in execution. Three camera perspectives ensured that all ergonomic, mechanical and organizational aspects of the assembly were recorded in detail.

After the video analysis, the results were compared with the existing internal documentation. This revealed minor deviations and identified optimization potential. The students were able to confirm that STIHL Tirol already has a very high standard of production. At the same time, it was shown that the assembly processes are highly complex, which requires a correspondingly intensive training effort for employees.

EFFECTIVE COOPERATION AND SUSTAINABLE RESULTS

The cooperation between the students and STIHL Tirol was assessed as extremely positive by both sides. The open exchange enabled both partners to gain valuable insights.

THE PROJECT COOPERATION WAS EXCELLENT. WE ARE PLEASED WITH THE INPUT FROM KUFSTEIN TIROL UNIVERSITY OF APPLIED SCIENCES AND WILL PROPOSE A FOLLOW-UP PROJECT.

Hansjörg Geisler

Production manager at STIHL Tyrol

SUPPORT FROM THE ELEARNING CENTER

The eLearning Center of the University of Applied Sciences Kufstein Tirol played a central role in the technical implementation of the project. It provided all the video equipment, supported the students full-time on both days of shooting, and took over the synchronization and editing of the material. The aim is to use the videos created as teaching material for future training courses. A comprehensive utilization concept is currently being developed in follow-up projects.

LONG-TERM IMPACT AND FOLLOW-UP PROJECTS

The project provided valuable insights that are of great benefit to both STIHL Tirol and the students. A direct implementation has already taken place through the adaptation of the existing documentation to the current actual processes.

WE LEARNED A LOT DURING THE PROJECT AND GAINED A DEEP INSIGHT INTO PRODUCTION AND THE FAMILY-ORIENTED APPROACH AT STIHL TIROL.

Voice of the student team

For the students at the University of Applied Sciences Kufstein Tirol, the project means valuable practical experience that will also be used in teaching. Future student groups in the Industrial Engineering, ERP Systems & Business Process Management and Smart Products & Solutions degree programs will benefit from the knowledge gained.

The close cooperation between STIHL Tirol and the FH Kufstein Tirol will be continued and intensified with a follow-up project that is already in the works.