LEAN Lab

The Kufstein University of Applied Science's LEAN Lab is an innovative training factory in which operational excellence can be achieved through the clear teaching of methods.

Students, company managers and employees in other positions can learn improved approaches to solving business problems.

The LEAN Lab is the product of a long-standing cooperation between various companies and the Kufstein University of Applied Sciences' Master's degree program ERP Systems & Business Process Management.

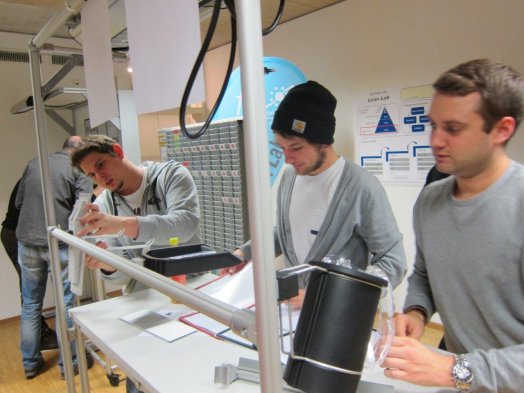

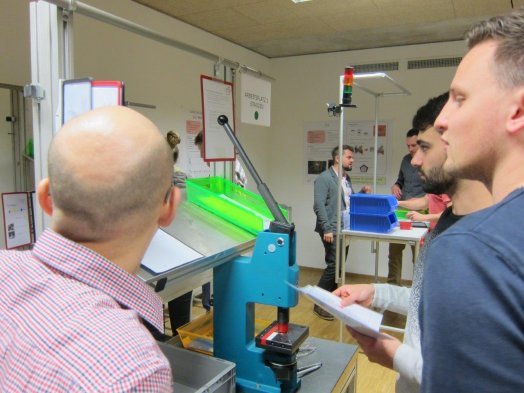

Realistic Learning Environment

Using real machines, the LEAN Lab simulates a realistic production line with its corresponding administrative areas.

The lab consists of mechanical processing jobs as well as assembly workstations which can be used to make a real product and incorporated into the whole production line as needed.

|

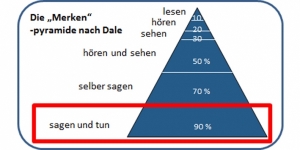

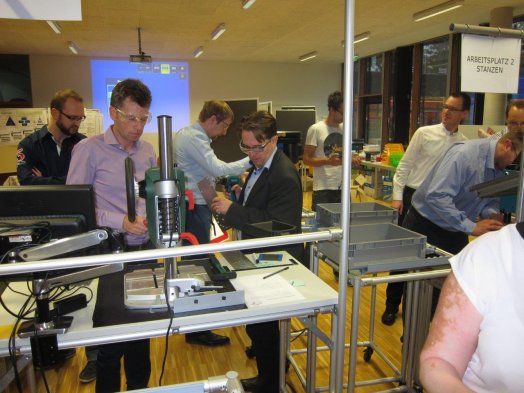

Learning, self-experiencing and having fun

A central element of work in the LEAN Lab is the close connection between the theory behind skills and the practical application thereof.

Because just reading and listening is not enough. Only once learners can do a task themselves, gain experience and subsequently reflect on their performance, can they learn with a lasting effect.

|

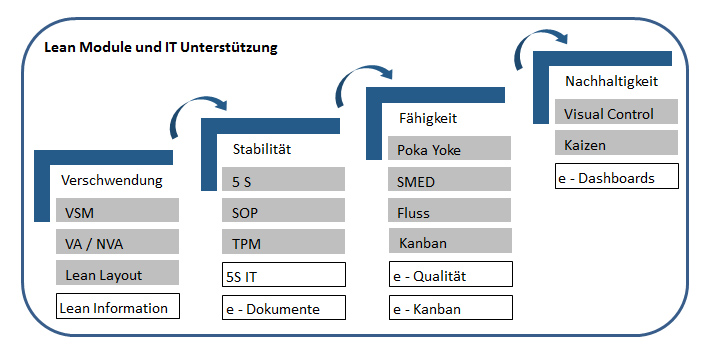

Bridging the gap between strategy, processes and IT

The LEAN Lab can be used to teach approaches and methods regarding operational excellence.

By including ERP systems and connecting them to production-related IT, the advantages of digitalization and Industry 4.0 become visible in a lean environment. |

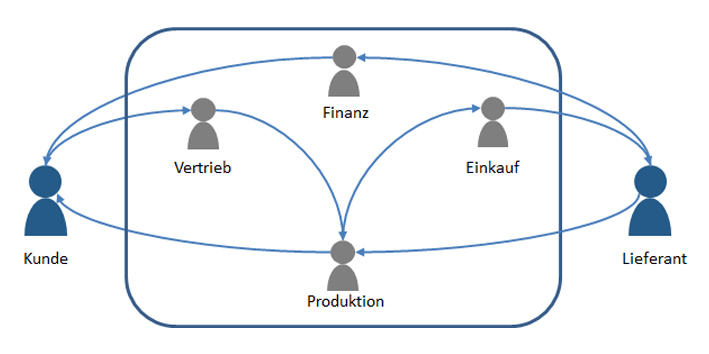

Lean Administration and Supply Chain

With production as a starting point, the LEAN Lab's lean philosophy can be applied to a whole company and its suppliers. That way, the whole supply chain can be optimized.n.